DCBA oversaw an energy makeover for The Wrentham Developmental Center, a Division of Capital Asset Management and Maintenance (DCAMM) project. The first phase of this U.S. Dept. of Energy Better Buildings Challenge Showcase Project included the installation of a new steam boiler system, as well as lighting and lighting control upgrades. The second phase focused on building a one‐acre solar array, beginning with soil testing, site preparation, and excavation for underground wiring. In total, the project team installed 1,672 solar panels, each producing 300 watts of energy. At completion, DCAMM concluded that the energy upgrades and solar array would provide approximately $1.4 million in annual energy savings.

DCBA transformed a 60,000‐sq. ft. warehouse into a work environment that included R&D space, manufacturing and production areas, and a product showroom. This project involved extensive MEP+FP infrastructure construction and media connections in conference rooms, as well as audio/visual and security packages. Client communication ensured that new mechanical, electrical, plumbing, and telecommunication systems were compatible with existing equipment. The design‐build scope for electrical and HVAC included in‐depth investigations of existing infrastructure to evaluate modifications needed.

This project was a global feat for DCBA, requiring precise installation as well as 12,000 tons of steel, 150 miles of welds, 30 miles of cabling, 650‐plus tractor trailer trips, and several‐hundred‐ton crane picks.

In addition to overseeing the construction team and over 450 contracts, DCBA recorded data, created necessary departments within the start‐up organization, established processes, and provided leadership insight to help strengthen the client’s capability of future projects. Additionally, DCBA retroactively organized project documents and information while imposing new scope, procurement, quality, schedule, and project controls.

This project required DCBA to create a new reliability lab for the testing of equipment manufactured as well as improved office space. Work consisted of reconfiguring the mechanical systems, including adapting the HVAC infrastructure by adding a new air handling unit, roof top unit, exhaust fans, and branch ducts, etc. to accommodate ventilation requirements. The electrical scope required workers to add wire mold and an associated transformer to handle increased power demands. New acoustical panels were installed on the walls and above the ceiling to address future noise concerns for adjacent users. DCBA coordinated access and shut downs with building facilities.

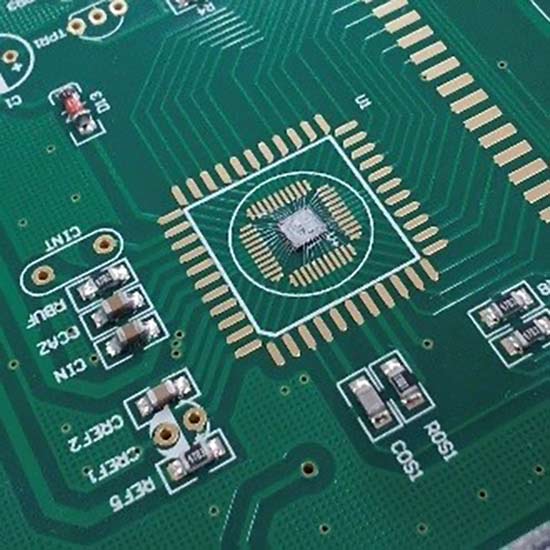

For this project, DCBA constructed a chip manufacturing laboratory in a highly-secure space. This included connecting the new production lab to an existing active lab and coordinating trades and personnel with building security.

The client required special noise and vibration isolation for chip production, and the construction space required contractors meet special status conductivity levels. Acoustical and noise requirements were successfully met for the facility through vibration isolation of all equipment and structures. In addition to the laboratory, DCBA installed a 6,000 sq. ft. roofing system over the winter without shutting down the facility. The project required highly-secure facility clearances for all DCBA staff and contractors.

This 33,000 sf. ft. project centered on the renovation of a process development cleanroom laboratory and support offices near operational laboratories. DCBA managed the overhaul of laboratory infrastructure for RO/DI water and clean process utilities. Workers installed a cooling system for a new Autoclave, a parts washer, new casework, new security, HVAC, electrical systems, and several Bio-Safety Cabinets. Additional work involved upgrading safety showers, eyewash stations, and miscellaneous architectural improvements as well as finalizing new AV systems for conference rooms.

This project involved the transformation of an aged, mixed-use building into a cutting-edge design and manufacturing facility with a focus on 3-D printing and design for the automotive and aerospace industry. DCBA coordinated design options for the architectural, structural and civil design of the building as well as the fire protection, HVAC and plumbing engineering systems. These updates were necessary in order to meet both current building codes/regulations and client’s current/future needs. As a design-build project, this undertaking required well-managed coordination and communication between DCBA staff and more than a dozen of carefully selected subcontractors to ensure the safe and successful delivery of this project.

This innovative industrial renewable energy project was undertaken in order to provide the Nuvera Hydrogen Generation Station at Golden State Foods in Chicago with high-purity hydrogen generation and a dispensing system to power fuel cell vehicles. DCBA installed hundreds of feet of high-pressure hydrogen coil tubing, which required meticulous coordination in order to avoid conflicts with existing MEPs. At the same time, workers reduced the number of fittings, ensuring that hazardous classification zones were not created within the existing facility. Workers also installed intricate instrumentation and controls, high pressure vessels, redundant low-pressure storage and equipment cooling systems, compressor skids, and a process generator. This project was completed without a single open flame.